Carbon dioxide sensor testing is one of the many behind the scene tasks we perform every day at CO2Meter.

I was looking online at a new consumer product designed to monitor CO2. The product was well designed. The sensor inside was small. I was sure our customers would like it.

So I sent an email with a link to Ray Hicks, our Chief Engineer. I got short reply:

“Know the product, it’s poor performing. We tested it, but it’s not stable, I have a dozen of those CO2 sensors in a box on the shelf.”

What many of our clients don't realize is that for every CO2 gas sensor module we sell, there are three more sitting in a dusty bin on a shelf you will never see and we will never sell.

How CO2 Sensors are Discovered

It starts with Travis Lenander, President of CO2Meter or one of our sales engineers who travel worldwide to sensor trade shows. Some of the best sensors designed are first available at SENSOR+TEST in Germany or Smart Sensor in Korea. Our team has visited or exhibited at the AHR Expo in the United States for over a decade to learn about the latest in indoor air quality products.

Once we find a sensor that meets a specific customer need or fills a gap in our product lineup, we will arrange a visit to the manufacturer's production plant where the sensor is assembled. Many sensors are designed in Europe or the United States, but manufactured in Asia. If we are satisfied with the quality control of the production process, the next step is to order a batch of sensors for in-depth analysis.

How CO2 Sensors are Tested

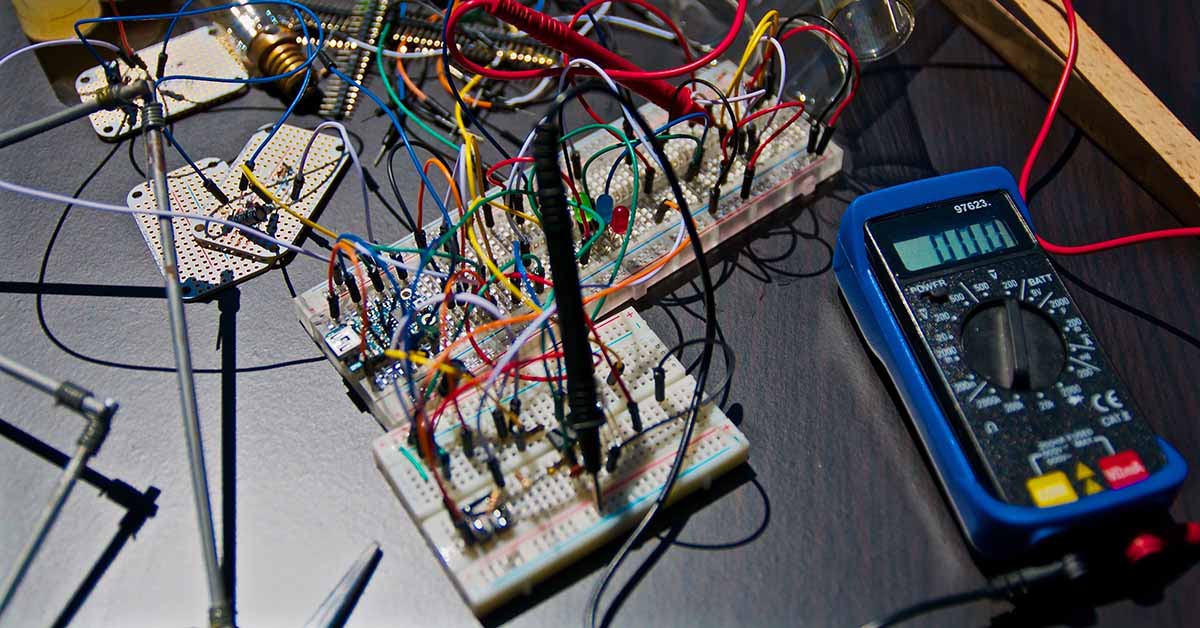

When sensors arrive at our facility, our in-house engineers spend hundreds of hours testing them for accuracy and repeatability. They testing I/O (signal input and output) to verify functionality. If the sensor performs reliably to the manufacturer's stated specifications our engineers will add new code to our free Gaslab® software to make it easy for OEMs to communicate with the sensors during application development.

But we’re not finished testing yet. Depending on the application, some new sensors are given to a select group of electronics experimenters, researchers or "early adopters" around the country who integrate them into projects and report back their real-world results. We follow up closely on their progress and report back to our engineers any problems in the field.

Throughout this entire process, our engineers exchange emails with the manufacturer’s engineers to request low-level documentation, undocumented features, or to ask for changes to make the sensors easier to use. It is not uncommon for us to receive binary code to re-flash an entire batch of sensor’s ROM memory before we make them available to customers.

For example, the most common UART (serial port) configuration in asynchronous mode is 9600/8/N/1. If a sensor doesn’t use this industry standard (some don't), we’ll ask the manufacturer to change it before we offer it to our customers. The same goes for I2C, analog voltage or digital I/O outputs.

In addition to testing by our engineers, we continuously collect customer feedback and sent it back to the manufacturers. This cycle benefits everyone as the sensors continue to evolve and improve.

Only after a sensor passes through this gauntlet do we begin to stock it in quantity to make it available for sale online.

But we're not done yet. We monitor and follow up on every return we get from the field. If we notice a high failure rate, we'll pull the product and repair or replace the defective sensors already in the field.

How CO2 Sensors are Sold

Other companies may offer the same sensor module online, but they have never actually bench-tested it. Everything they know about a sensor is printed on the manufacturer’s data sheet. Instead, they take an order online, pass it on to the manufacturer, let the customer wait 4-6 weeks for delivery, and keep the difference between the retail price and wholesale cost as profit.

At CO2Meter, we pride ourselves in knowing how each of our products work intimately.

And because of our intimate knowledge of the sensors we sell, manufacturers worldwide send their customer requests for technical support to us. We also serve as a liaison between overseas manufacturers and OEM users to make shipping easy and just-in-time delivery dependable. For large-quantity orders, we even negotiate with the manufacturers to get our customers the lowest possible volume pricing.

Why it Matters

All this sensor knowledge helps our customers in three important ways.

- It makes our customer service team much more knowledgeable about gas sensors when making a recommendation for a project or device.

- We only use the best sensors available when we design our own products like the CO2 + RH/T Data Logger to test indoor air quality.

- It gives us very happy customers.

Do We Get it Wrong?

Do we get it wrong? Occasionally yes. Ray tells a story about a CO2 sensor we were very excited about for cell culture incubation and live animal applications. The sensor even briefly appeared on our website, although we didn’t put it in the field. Ultimately we couldn’t trust it, so we took it off the website. It wasn’t until later during a visit to the vendor that we discovered the sensor's production had been sub-contracted to a “back water” factory with no quality control. It was a huge waste of both time and money, but you can still find that sensor on other websites for sale today.

So the next time you see one of our gas sensor modules on the CO2Meter.com website or in a newsletter article, I hope you appreciate the fact that it is one of the best available. We stand behind all the products we sell.