Over the past few years, the craft brewing industry is finding themselves increasingly accountable and liable for meeting and adhering to OSHA's workplace regulations.

The Occupational Safety and Health Administration (OSHA) includes policies and programs that breweries must comply with to keep their employees safe and ensure their facilities meet standards.

While carbon dioxide (CO2) gas is an important component of the brewing process, it is also a hazard at elevated levels. It's up to you to keep yourself, your employees, and customers safe.

By providing this overview on OSHA regulations, violations and compliance we hope to provide you with some idea about safety best practices and help lead your brewery towards a safer workplace.

What is OSHA?

The Occupational Safety and Health Administration (OSHA) is one agency within the United States Department of Labor. The 1970 OSHA Act created OSHA, which sets and enforces protection for employee’s working conditions.

The basic responsibilities for an employer is to be aware of and follow OSHA guidelines for your business.

Since all OSHA standards and regulations are free, you cannot claim “I didn’t know” as a reason for not following the OSHA guidelines.

You can read your list of general responsibilities here.

Craft breweries have experienced nearly 4X as many safety violations compared to the larger breweries to date. It is crucial that craft breweries understand and educate their staff's on the hazards and how to mitigate them too.

Does OSHA cover breweries?

Yes, OSHA covers breweries just like any other workplace. Breweries are subject to OSHA regulations to ensure the safety and health of workers. OSHA standards address various aspects of workplace safety, including machinery safety, chemical exposure, electrical hazards, and more. Breweries need to comply with these standards to maintain a safe working environment for their employees.

Is Your Brewery Subject to OSHA Oversight?

If you have a single employee you are subject to OSHA oversight. OSHA regulations cover all 50 states. Additionally, approximately half the states have an OSHA-approved state program, which in some cases are even stricter than the federal regulations.

Classifying employees as independent contractors doesn’t necessarily relieve the brewery owner of liability. While self-employed individuals are not technically covered by the OSHA Act, "Employers cannot evade their responsibility by claiming that workers on a job site are independent contractors" according to a 2016 ruling by an OSHA Administrative Law Judge.

Additionally, claiming that you "didn't know the OSHA regulation existed" is not a viable excuse either.

Staying ahead of the game on safety regulations, preparations, signage and compliant CO2 safety devices is the first step to ensuring you are following requirements and will be "A-OK" for inspection.

Are OSHA Inspections and Standards Common?

OSHA inspections are usually triggered by an accident or fatality in the workplace, or by employee complaints. However, they can also be the result of random inspections.

According to this article in Craft Brewing Business, OSHA is increasingly aggressive in enforcing workplace safety requirements on breweries, beverage dispensing industries, and employers. In 2016 OSHA placed approximately 700 breweries on a “bad actor list.” Once you’re on the list, you can plan on significantly more OSHA visits and increased fines.

What are the Most Common Violations?

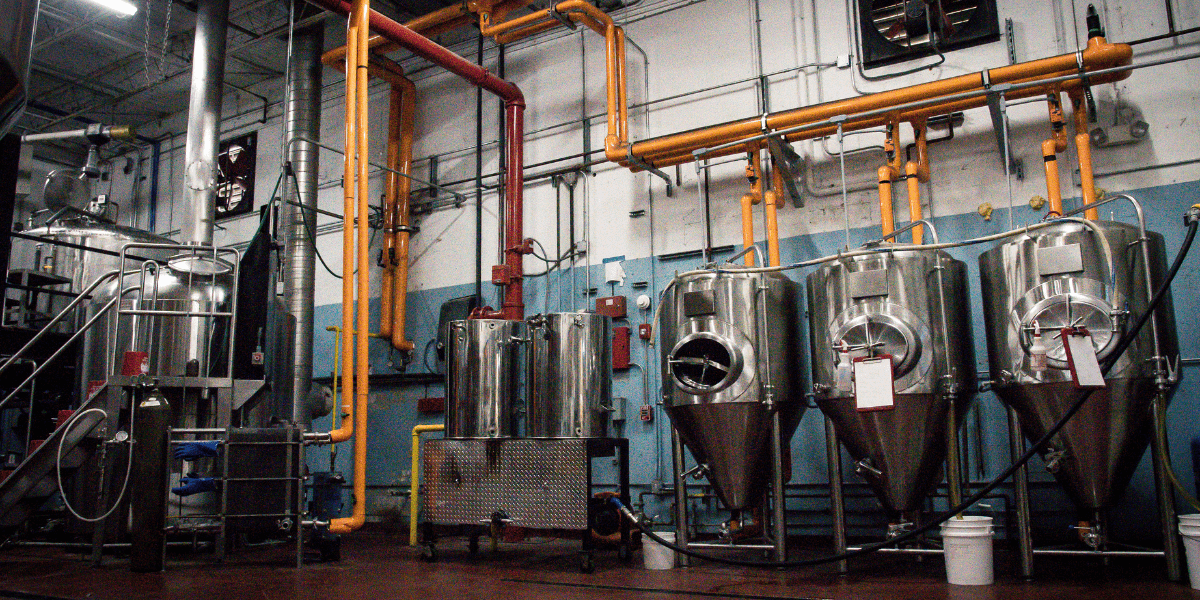

Gabriel Sierra, managing director of Prometrix Safety Consulting says the most common OSHA violations include lockout/tag-out and confined spaces accidents. Both of these kinds of incidents can occur in breweries where fermenters, grain silos, kettles and other machinery are used.

OSHA standard 1910.146 defines a “permit-required confined space” as:

- Is large enough and so configured that an employee can bodily enter and perform assigned work; and has limited or restricted means for entry or exit (for example, tanks, vessels, silos, storage bins, hoppers, vaults, and pits are spaces that may have limited means of entry.); and is not designed for continuous employee occupancy.

This rule is designed to help prevent tragic situations like this where a construction foreman died from asphyxiation after entering a manhole with an uncontrolled hazardous atmosphere.

Helpful Fact? The "walk around inspection" portion is the most important part of the OSHA inspection process and majority of violations are identified during this phase. (plan ahead!)

To help small businesses become compliant, OSHA has published the Small Entity Compliance Guide (pdf). This is a plain language explanation of all aspects of the Confined Space in Construction Rule, including how eliminating or isolating any hazards can allow you to reclassify a permit required confined space as a non-permit confined space.

If you own or work in a brewery, you already have a good idea what a confined space is, and how potentially dangerous they can be.

In addition to confined spaces, ergonomic violations are commonly cited under the OSHA General Duty Clause. This means that worker tasks like transporting kegs or lifting bags must be designed in such a way as to minimize employee hazards. While working in a brewery always involves physical labor it is up to the employer to mitigate the dangers involved with lifting tasks.

One commonly overlooked danger is allowing untrained employees to drive vehicles, especially forklifts. OSHA's requirements for forklifts and powered trucks can be found in “Powered Industrial Trucks 1910.178.” This includes:

- The employer shall ensure that each powered industrial truck operator is competent to operate a powered industrial truck safely, as demonstrated by the successful completion of the training and evaluation. Training shall consist of a combination of formal instruction (e.g., lecture, discussion, interactive computer learning, video tape, written material), practical training (demonstrations performed by the trainer and practical exercises performed by the trainee), and evaluation of the operator's performance in the workplace. All operator training and evaluation shall be conducted by persons who have the knowledge, training, and experience to train powered industrial truck operators and evaluate their competence. Certification. The employer shall certify that each operator has been trained and evaluated as required by this paragraph (l). The certification shall include the name of the operator, the date of the training, the date of the evaluation, and the identity of the person(s) performing the training or evaluation.

What are the hazards of CO2 in breweries?

There are many hazards that brewers can encounter when it comes to working with carbon dioxide in the brewery. To start, carbon dioxide (CO2) is commonly used for carbonation, purging, and packaging processes. However, while this gas is essential for these operations, it still poses severe negative health effects/hazards if not handled properly.

We highlight the most common hazards below:

- Asphyxiation: CO2 is heavier than air and can accumulate in poorly ventilated or confined spaces, displacing oxygen and creating an asphyxiation risk. Brewery workers can suffocate if they enter these areas without proper safety precautions.

- Toxicity: At high concentrations, CO2 can be toxic and cause symptoms such as headaches, dizziness, confusion, and even loss of consciousness. Prolonged exposure to elevated CO2 levels can lead to more severe health effects.

- Explosion: CO2 is stored in high-pressure cylinders or tanks, and if these containers are damaged or mishandled, they can rupture or explode, causing injury or property damage.

- Fire Hazard: While CO2 itself is not flammable, it can displace oxygen in the air, potentially causing combustion hazards. In the presence of a fire, CO2 can also react with certain substances to produce flammable or explosive mixtures.

- Skin and Eye Irritation: Contact with liquid CO2 or high concentrations of CO2 gas can cause irritation to the skin, eyes, and mucous membranes.

Brewery Safety Rules

Adhering to brewery safety rules is essential for the well-being of employees, legal compliance, product quality, operational efficiency, and the reputation and financial health of the brewery.

Further, by following brewery safety rules this helps prevent injuries and illnesses among brewery employees on the job. Such injuries could include accidents, slips and falls, chemical exposures, burns, and serious equipment-related injuries. When safety rules are implemented, it maintains employee safeguard and can also aid in breweries meeting compliance with the overall safety regulations and standards.

Overall, a commitment to safety not only protects employees but also safeguards the reputation of the brewery. A workplace known for its safety culture is more attractive to potential employees, customers, and business partners.

Some of the most common brewery safety rules include, but are not limited to:

-

Personal Protective Equipment (PPE): Employees should wear appropriate PPE such as safety glasses, gloves, steel-toed boots, and hearing protection to prevent injuries from slips, falls, cuts, burns, or exposure to chemicals.

-

Machine Safety: Machinery used in brewing, such as bottling lines, fermentation tanks, and forklifts, should be properly maintained and operated according to safety procedures to prevent accidents.

-

Chemical Safety: Employees should be trained on handling and storing chemicals used in brewing, such as cleaning agents and sanitizers, to prevent chemical burns or respiratory issues.

-

Electrical Safety: Electrical equipment should be inspected regularly, and employees should be trained to recognize and avoid electrical hazards to prevent shocks or fires.

-

Slip and Fall Prevention: Brewery floors should be kept clean and dry to prevent slips and falls. Non-slip flooring and proper drainage systems can help minimize the risk of accidents.

-

Confined Space Safety: Employees should be trained on confined space entry procedures and equipped with appropriate gear when working in confined spaces such as fermentation tanks or grain silos to prevent suffocation or entrapment.

-

Lifting and Ergonomics: Proper lifting techniques should be used to prevent back injuries, and ergonomic workstations should be provided to reduce strain and musculoskeletal disorders.

-

Fire Safety: Fire extinguishers should be readily available, and employees should be trained on fire evacuation procedures to respond quickly and effectively in case of a fire.

-

Emergency Response: Emergency response plans should be in place, including procedures for medical emergencies, chemical spills, and other potential hazards.

-

Training and Education: Regular safety training should be provided to all employees to ensure they are aware of potential hazards and know how to work safely in the brewery environment.

Brewery Safety Checklist

While you should do your own homework, here’s an overview of what OSHA expects you to have in your brewery:

- Safety data sheets (SDS, formerly MSDS) on all gas and liquids used in the brewery.

- Instruction in OSHA regulations relating to ergonomics, walking and working surfaces, fall protection, confined spaces, powered industrial trucks, chemical safety and personal protective equipment.

- A written (and tested) emergency evacuation plan, confined space protocol and chemical safety plan.Know and follow OSHA injury reporting regulations.

- Develop a process that allows employees to report safety concerns and incidents to the owner without fear of retaliation.

- Regular safety meetings and training for employees that address all of the above.

For many breweries the plan can be completed by working with a Safety consultant in combination with the insurance company. Brewers may even be eligible for lower cost insurance once all safety protocols have been completed.

If you don't have a copy you should also be familiar with OSHA's Small Business Handbook.

How to Comply with OSHA Brewery Safety Requirements

For breweries, where money is always tight, a good place to start is the free online brewery safety training courses sponsored by the Brewer’s Association. These courses are not only free, but provide testing and certification that proves you or your employees have been trained on safety related issues. In addition, they have a Q&A section where common issues are addressed.

If you have an inspection coming up and think you aren’t prepared, start by reviewing the BA's training documents.

Note these courses are paid for by the members of the Craft Brewers Association, of which CO2Meter is an industry member.

Cost of OSHA Compliance

Many brewers see only the cost associated with safety monitoring and gas detection, causing them to shy away from devices. However, the cost of an employee incident is far greater. Increased OSHA presence, increased insurance, damage to reputation in the community and in the industry, not to mention the extremely high cost to an employee.

OSHA has a free tool online that lets brewers compute the cost of an accident by using your business information and selecting the type of accident. Here's a sample of the cost averages taken from OSHA's database:

| Injury Type | Average Cost |

| AMPUTATION | $88,991 |

| ASPHYXIATION | $214,567 |

| BURN | $43,661 |

| ELECTRIC SHOCK | $120,024 |

| POISONING - CHEMICAL (OTHER THAN METALS) | $58,019 |

| RESPIRATORY DISORDERS (GASES, FUMES, CHEMICALS, ETC.) | $34,577 |

| RUPTURE | $71,460 |

We understand when brewery owners and managers comment "we can’t afford brewery safety equipment.” But can you afford NOT to install safety monitors to ensure the safety of your most valuable assets - your employees?

CO2 Safety Alarm for Breweries

In addition to personal safety, some state and local municipalities have added Fire Code compliance in addition to the OSHA exposure limits to bulk CO2 storage safety alarm specifications.

To meet this requirement, CO2Meter offers the RAD-0102-6 that meets OSHA requirements. This wall mount device was designed to meet the OSHA time-weighted average (TWA) personal exposure limit (PEL) for CO2.

Brewers also choose the Carbon Dioxide (CO2) Fixed Gas Detector w/ Remote Sensor (0-5%) for it's ability to hold more than 1 sensor, allowing brewers to monitor both Carbon Dioxide and Nitrogen or several rooms at once. This device also meets compliance standards and requirements.

The National Institute for Occupational Safety and Health (NIOSH) CAS No. 124-38-9 requirement followed by OSHA says that the average CO2 level a worker can be exposed to over an 8-hour day can be no more than 5,000ppm Time Weighted Average (TWA), the half short term exposure limit (1/2 STEL) can be no more than 15,000 ppm and the full short term exposure limit (Full STEL) cannot exceed 30,000ppm (3%). The RAD-0102-6 meets all these requirements.

Learn more about Selecting the Right CO2 Storage Safety Alarm.

CO2Meter believes that with proper knowledge and education about OSHA, fire codes, brewery safety, and CO2 monitoring we can protect craft breweries prior to inspection and ensure compliance across the board.

For more information on CO2 Safety Monitoring and Meeting OSHA Brewing Safety Requirements, contact us today.