Every sensor that measures a variable requires calibration. Calibration is the process of matching a sensor’s output to a known standard. If the two do not match, the sensor’s output is adjusted. If they match, the sensor is considered “calibrated.”

For example, when you set your home thermostat to 68 degrees Fahrenheit you expect it to turn the furnace on when the sensor reads 68 degrees. But how does a thermostat know what “68" or "degrees” is? The simple answer is that the thermostat was span calibrated to a known scale between 2 points: the temperature at which pure water freezes and its boiling point. These data points are used to precisely calibrate the sensor.

For gas sensors there are 3 methods of calibration:

- Span (2-point) calibration

- Single point calibration

- Automatic Background Calibration

Span Calibration

Span or 2-point calibration is performed at the factory immediately after a gas sensor is manufactured or occasionally in the field. To perform a span calibration, a gas sensor is exposed to 2 gases, one with no target gas, and one with a known amount of the target gas.

Span calibration begins by exposing the sensor to a pure inert gas like nitrogen or argon. In the case of oxygen sensor calibration, the sensor’s reading for 0% oxygen is recorded in the sensor’s EPROM memory.

Next, the sensor is exposed to a known percentage of gas, often the highest level for which the sensor is rated. For example, a 25% oxygen sensor would be calibrated with 25% oxygen with the balance of the gas nitrogen or argon. After being exposed to the second known gas, the sensor's response is also recorded in the sensor's memory.

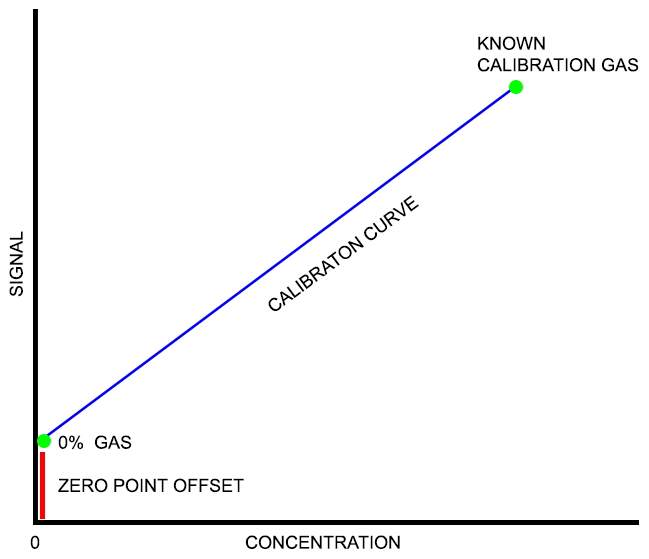

Once these 2 points are known, a linear response to the gas concentration between the 2 points can be assumed. This is known as a calibration curve and is shown in the image above in blue.

In theory, every gas level readings between the 2 calibration points should fall on the blue line. In reality, some gas sensors do not have a precise linear response to different amounts of the target gas. In these cases, the manufacturer may perform 4 or more point calibrations to create a curved response line instead of a straight line.

Once the calibration curve is known, a calculation is performed in the sensor's memory so that for every gas level a concentration can be computed. This calculation may be as simple as a slope intercept for a straight line, or in the case of a curve, a slope of a curve formula called the derivative.

During span calibration, a second value called the zero-point adjustment is stored in the sensor's memory. The zero-point adjustment is what the sensor reads when it is exposed to the zero calibration gas. This difference (shown as the red line in the image) is saved as an offset to the sensor’s actual reading when exposed to 0% gas.

For example, If an oxygen sensor reads 0.01% when exposed to 0.0% oxygen, a negative offset of “-0.01%” is stored in the sensor’s memory and applied to all future readings.

Although the terms are used interchangeably, calibration is not the same as zero-point adjustment. While zero-point adjustment gives a more accurate sensor reading, span calibration is first required to match the sensor’s response curve to a known target gas.

While span calibration is always performed at the factory on every new sensor, in cases where precise accuracy is required, it may also be performed again in the field or by returning the sensor to the manufacturer.

Single Point Calibration

Single point calibration is used when only one measurement point of a gas sensor is needed. It is useful in cases where maximum accuracy is less important than total cost. This is especially important when the sensor cannot be easily removed or taken out of service for bench top recalibration, or where there is not trained staff to perform the procedure.

In most cases single point calibration is achieved in fresh air. Fresh air contains approximately 78% nitrogen, 20.9% oxygen, 0.9% argon and 400ppm (parts-per-million) of carbon dioxide. All other trace gases should be less than a few parts per million. Knowing this, any gas sensor exposed to fresh air should match one of these readings. Any deviation is evidence of too much (or in the case of oxygen) too little gas.

Single point calibration is only possible because the gas sensor was originally exposed to span calibration during manufacturing. Once the calibration curve is stored in the sensor’s internal memory, single point calibration is used like the zero-point offset.

For example, if a CO2 sensor uses single point calibration when the “calibrate” button is pressed on the device in fresh air, the sensor’s software assumes the current stable reading is 400ppm CO2 and adjusts the curve with an offset value. If a carbon monoxide sensor uses single point calibration in fresh air, pressing the calibrate button tells the sensor that there is no CO present and to save any offset to the zero point.

Automatic Background Calibration

Manufacturers of early CO2 sensors used in buildings to measure occupancy or indoor air quality (IAQ) levels realized the difficulty of calibrating wall-mounted gas monitors. Removing the units from the wall to bench calibrate was expensive, required trained staff, and with budget cuts calibration schedules were often ignored.

To solve the problem of indoor air quality CO2 sensor calibration in the field, Senseair AB of Sweden developed a technique known as Automatic Baseline Calibration (ABC). The theory behind ABC is that at some point each day a room is unoccupied. The CO2 level should return to 400ppm, the same as outdoor air. By storing the lowest CO2 readings taken over several days in EPROM memory, an offset to 400ppm could be calculated, then added or subtracted from the actual CO2 reading displayed.

While it is called automatic background calibration, in reality it is automated version of single-point calibration. And like single-point calibration, a span calibration curve was originally saved in the sensor's memory at the factory. For maximum accuracy, even devices that use ABC should be calibrated over time.

The advantage of automatic background calibration is that the CO2 sensor is self-zeroing over the life of the sensor. The disadvantage is that if the sensor never “reads” normal 400ppm air, over time it will display inaccurate CO2 levels. Learn more about ABC calibration here.

How often should a sensor be calibrated?

The more accurate a gas level reading required or the more deadly the gas, the more often the sensor should be calibrated. For science experiments, sensors are span calibrated repeatedly to verify the accuracy of published data. For personal gas safety monitors, single-point calibration on a daily basis (i.e. bump testing) may be required.

After working with hundreds of sensors and applications over the years, here are some general guidelines:

- Scientific Experimentation – Before each test

- Personal Safety – Monthly or daily bump-test recommended by OSHA

- Greenhouse – After each growing season

- Manufacturing – Bi-annually to annually

- Indoor Air Quality – Annually or longer if ABC calibration is used

Because these are only guidelines, calibration schedules may also be dictated by experimental protocols or by particular industrial standards. When deciding on a calibration schedule you should consult your specific sensor requirements for your application.